Loading... Please wait...

Loading... Please wait...SHOP NOW

Popular Brands

Our Newsletter

- Home

- Pearl Info & Size Chart

Pearl Info & Size Chart

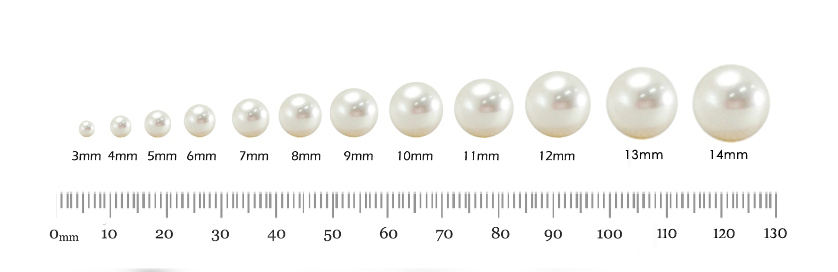

Size Chart

*The ruler is scaled to the pearls in the pictures.

*The picture has been scaled to approximately the actual size.

Pearl Cultivation

The Pearl is considered the only gemstone that is produced by a living essence in nature. Pearls can be refer to as natural or cultured. Natural pearls are pearls that have been found in mollusks in their natural environments.

They have absolutely no human intervention in creating the pearl. Cultured pearls are real pearls. They are by no means lesser in quality as natural pearls. Most pearls used today are cultured pearls.

The creation of cultured pearls begins with a tiny piece of mantle tissue or mother of pearl. The irritant is implanted into the mollusk (either an oyster or a mussel). The mollusk will coat the irritant with multiple layers of substance known as nacre. Overtime, the gradual coating develops in to what you see today, a pearl.

Pearl Farms

Pearl farms consist of acres of wired frames that are submerged into the bodies of freshwater. The mussels are attached to the frames and the frames are then suspended by a float. Pearl farms similar to the ones above, harvest pearls from the mussels every 1 to 4 years.

The farms maintain a balanced ecosystem for the mollusk to thrive in. They feed the fishes daily and keep the water clear of any pollutants. The results are healthier mollusks and better pearls. An intricate process of pearl cultivation is performed at the pearl farms. This process is the core to yielding the pearls you see today.

Types of Pearls

Cultivated pearls have two basic categories; freshwater pearls and saltwater pearls.

Tahitian Pearls, South Sea Pearls and Akoya Pearls are categorized under saltwater pearls. Saltwater pearls are cultivated using a piece of mother of pearl in oysters that live in tropical oceans or protected lagoons.

Freshwater Pearls are formed in mussels found in lakes, rivers, ponds, and other bodies of fresh water. Most farmers use mantle tissue to cultivate the pearl ; hence freshwater pearls are mostly made up of nacre. Due to this, freshwater pearls are more durable over the course of wear. Since each mussel can produce up to 40 pearls, freshwater pearls are the most common in the market.

The availability, affordability and recent increase in quality of freshwater pearls have shifted many consumers and designers toward freshwater pearls.

Factors of Quality

Color

Freshwater pearls exhibit a wide spectrum of colors. The prime natural colors include white, peach, lavender, and pink. However, it has become increasingly popular to color these pearls using heat treated methods.

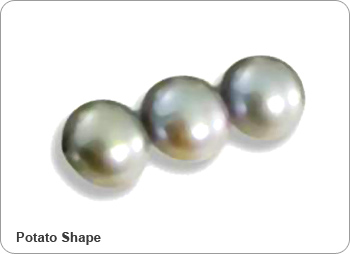

Shape

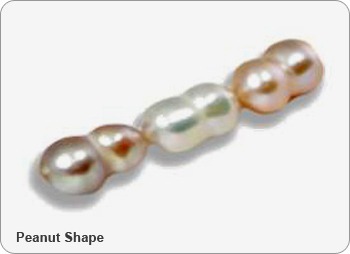

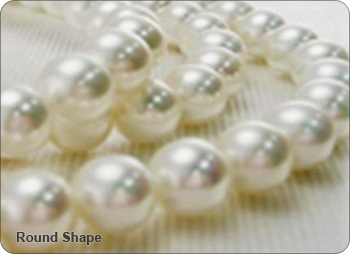

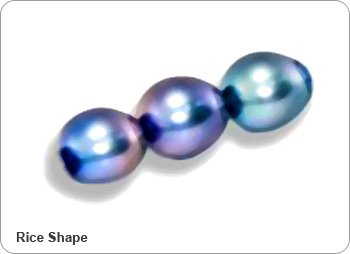

Pearls come in an array of shapes. The most ideal shape is round but completely uniform rounds only make up a small percentage of the pearls harvested every season.

Nacre

The nacre is what surrounds the bead or irritant placed into the mollusks. The thicker and smoother the nacre is; the more valuable the pearl. Desirable pearl nacre depends on the smoothness and relatively uniform coating. The nacre should be thick enough such that the nucleus of the pearl cannot be seen. Poor nacre coating can lead to pearls looking dull or chalky.

Luster

Luster is the intensive shine that a pearl possesses. It is the result of the reflection of light through the multiple layers of nacre. If the layers of nacre are smooth, the pearl will contain a better luster.

Surface Smoothness

When considering the quality of the pearl, it is important to bear in mind its surface. The cleaner surfaces contributes to a higher value. But the industry constantly experiments and create new designs, which have also made textured and circle pearls more desirable.

Size

When it comes to pearls, size does matter. Freshwater pearls can come in a range of sizes, from seed pearls as small as 1mm to pearls that are 15mm. Pearls below 4mm or above 10mm will have a higher price.

There is no universal grading system for pearls and it may differ from each pearl supplier. At Majestic™, we takes all these factors to grade and determine the quality of the pearls. This is usually reflected in the prices of the different pearls. We also color code the tags on our pearls to reflect that,

Pearl Shapes

Below are some shapes that pearls can come in. As the industry evolves, we always see new additions to this list.

Process of Pearls

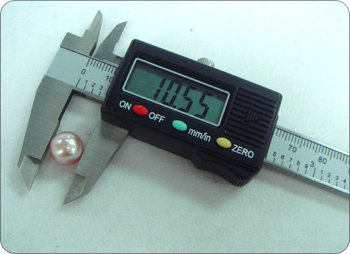

Pearl Measurement System

Our pearls are measured either in millimeters (mm) or grams (gm) and have a 0.5 mm or 5 gm variance between each size of the pearl.

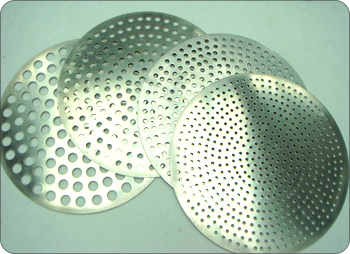

Coin Style, Biwa Style and Keshi Style pearls are usually measured by the weight (gms). Shapes such as round, potato, button, nugget, rice and head-drill are usually measured in mm. Specialized tools are used for measuring and sorting out the pearls. The gauge, metal sorting plates, sorting trays and heavier machinery are used to aid in distinguishing each pearl's size.

Process of Pearl Treatments

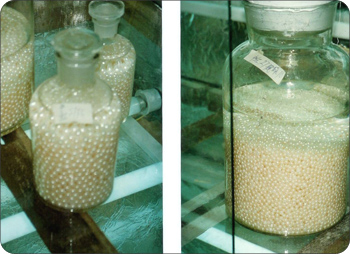

Washing - Once the raw materials are harvested from the mollusks, they are put through a wash to cleanse any remaining debris.

Sorting & Sizing - After the wash, the pearls are placed into machines that sort the pearls by shape and size. The machine consist of layers of sorting plates arranged in descending order. The pearls are repeatedly shuffle through the layers.

Drilling - The pearls are then taken to the next department for drilling. Each pearl is carefully drilled and prepared for the next phase.

Bleaching - Most pearls - including cultured saltwater, South Sea, and freshwater pearls - are bleached to lighten uneven dark areas. This is permanent. It provides a more uniform appearance and prepares the pearl for steps that can enhance the color.

Deep Cleaning - After the bleaching process, in some cases lasting as long as 60 days, the pearls are placed back into the washers for a thorough rinse.

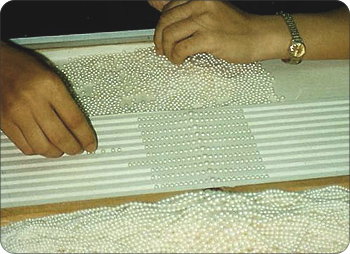

Matching and Stringing - Pearls are spread and are carefully picked through by workers. They match and string the pearls.

Color Treatment - As you can see in the market, freshwater pearls come in many colors. Blues, greens, reds and yellows could be achieve through practiced dyeing techniques. The strands of pearls are sent to these specialized facilities for all the color treatments.

The facilities in charge of dyeing the pearls have sent several samples for testing. All samples have a lead percentage lower than the permitable amount.

Polishing - The final step is polishing. A barrel like machine containing wax soaked bamboo pieces is slightly warmed before placing the pearls in.